Optimize Your Fleet’s Performance with Smart Maintenance Solutions

Fleet Maintenance Software:

Fleet Maintenance, Without the Chaos

One connected fleet platform to automate preventive maintenance, manage repairs, reduce downtime, and control maintenance costs across your entire fleet.

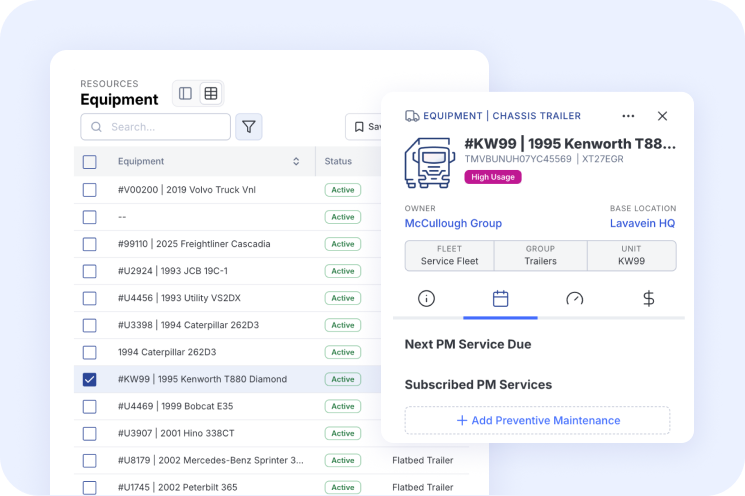

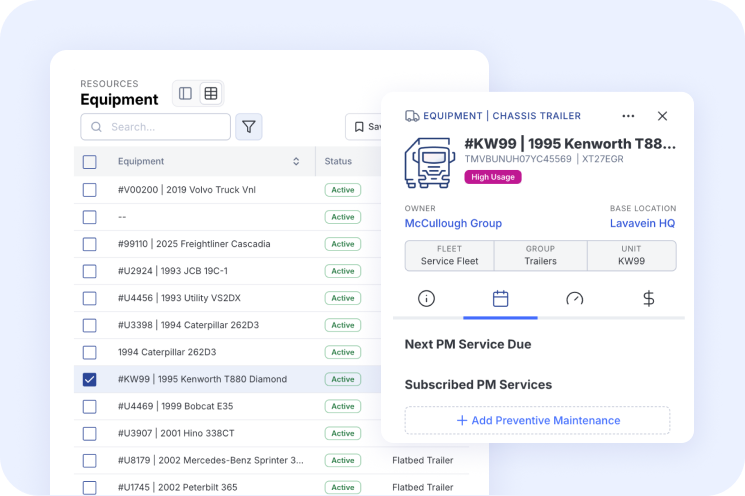

Preventive Maintenance Automation

Reduce downtime with proactive, data-driven fleet maintenance software.

![]() Automated PM schedules based on time, meter readings, mileage, or OEM recommendations, giving you flexibility across mixed fleets and asset types.

Automated PM schedules based on time, meter readings, mileage, or OEM recommendations, giving you flexibility across mixed fleets and asset types.

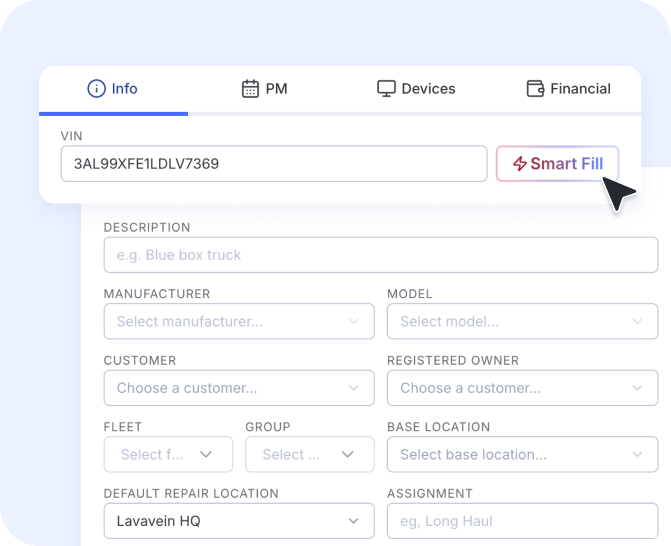

![]() Smart Fill instantly loads asset specs, PM schedules, and labor times using VIN decoding and Motor data, eliminating setup errors and manual entry.

Smart Fill instantly loads asset specs, PM schedules, and labor times using VIN decoding and Motor data, eliminating setup errors and manual entry.

![]() Real-time PM alerts and dashboards show what’s coming due, overdue, or at risk across locations.

Real-time PM alerts and dashboards show what’s coming due, overdue, or at risk across locations.

![]() Seamless connection to work orders and inspections, so scheduled maintenance turns into action without delays.

Seamless connection to work orders and inspections, so scheduled maintenance turns into action without delays.

![]() Reduce emergency repairs and unplanned downtime by up to 30% with proactive fleet maintenance planning.

Reduce emergency repairs and unplanned downtime by up to 30% with proactive fleet maintenance planning.

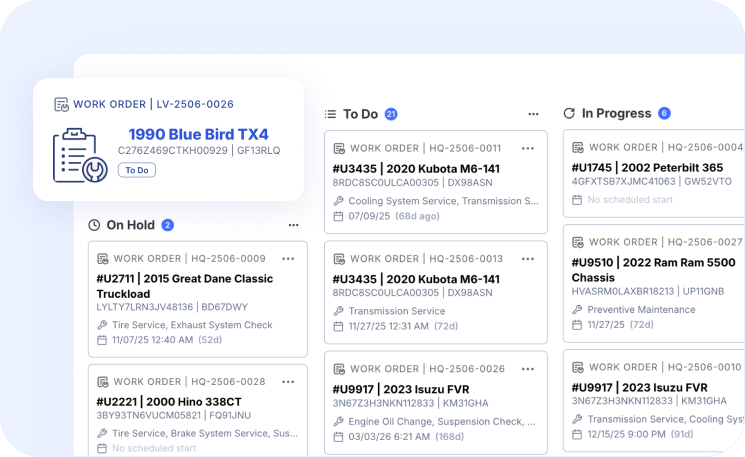

Work Order Management

Centralize repairs and keep every maintenance job moving without delays or guesswork.

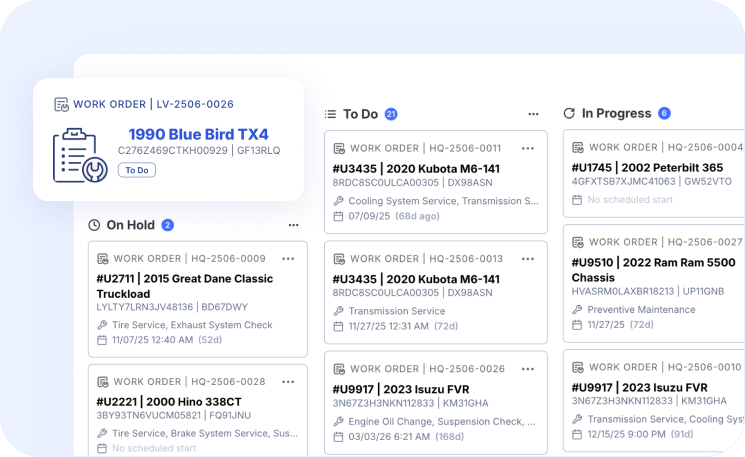

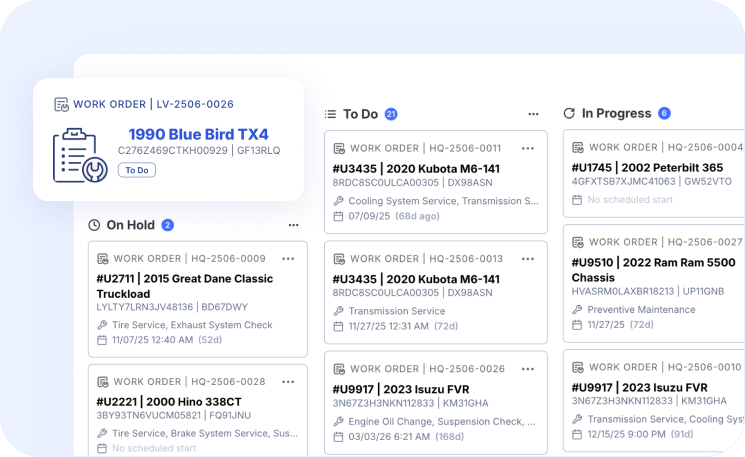

![]() Create and assign work orders instantly from preventive maintenance schedules, inspections, breakdowns, or service requests.

Create and assign work orders instantly from preventive maintenance schedules, inspections, breakdowns, or service requests.

![]() Track labor, parts, and costs in real time, giving you full visibility into every repair and true maintenance spend.

Track labor, parts, and costs in real time, giving you full visibility into every repair and true maintenance spend.

![]() Standardize workflows across shops and locations, ensuring consistent processes and cleaner data.

Standardize workflows across shops and locations, ensuring consistent processes and cleaner data.

![]() Live status updates and audit trails show what’s in progress, waiting on parts, or ready for release.

Live status updates and audit trails show what’s in progress, waiting on parts, or ready for release.

![]() Reduce work order processing time and improve turnaround time and fleet availability.

Reduce work order processing time and improve turnaround time and fleet availability.

Fleet Inspections

Catch issues early and turn inspections into action, not paperwork.

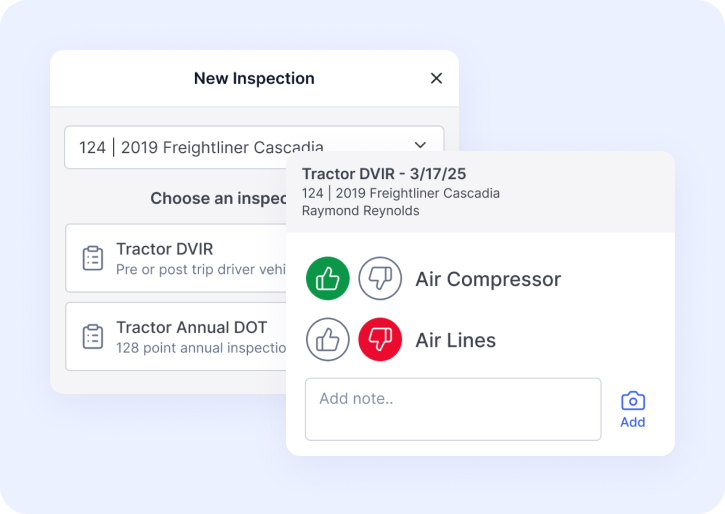

![]() Mobile pre-trip, post-trip, and custom inspection checklists ensure consistency across drivers, technicians, and locations.

Mobile pre-trip, post-trip, and custom inspection checklists ensure consistency across drivers, technicians, and locations.

![]() Inspection defects automatically generate work requests or work orders, eliminating manual follow-up.

Inspection defects automatically generate work requests or work orders, eliminating manual follow-up.

![]() Time-stamped digital records and audit trails support compliance and simplify audits.

Time-stamped digital records and audit trails support compliance and simplify audits.

![]() Fleet-wide visibility shows inspection completion rates, open defects, and recurring issues.

Fleet-wide visibility shows inspection completion rates, open defects, and recurring issues.

![]() Improve safety and reduce roadside failures by addressing problems before they turn into breakdowns.

Improve safety and reduce roadside failures by addressing problems before they turn into breakdowns.

Breakdown Management

Respond quickly to unexpected breakdowns and minimize disruptions across your fleet.

![]() Log roadside and unplanned breakdowns instantly from drivers, technicians, or dispatch.

Log roadside and unplanned breakdowns instantly from drivers, technicians, or dispatch.

![]() Automatically create and route breakdown work orders to the right shop, vendor, or technician.

Automatically create and route breakdown work orders to the right shop, vendor, or technician.

![]() Track downtime, repair status, labor, parts, and vendor costs in real time for full visibility.

Track downtime, repair status, labor, parts, and vendor costs in real time for full visibility.

![]() Coordinate emergency repairs and outside work without losing cost control or documentation.

Coordinate emergency repairs and outside work without losing cost control or documentation.

![]() Reduce extended downtime and get vehicles back in service faster with structured breakdown workflows.

Reduce extended downtime and get vehicles back in service faster with structured breakdown workflows.

Vendor Management (Outside Work)

Maintain full visibility and control over maintenance performed by third-party vendors.

![]() Track outsourced repairs, warranty work, and emergency services in one centralized system.

Track outsourced repairs, warranty work, and emergency services in one centralized system.

![]() Automatically create outside work orders and tie vendor work directly to assets and maintenance history.

Automatically create outside work orders and tie vendor work directly to assets and maintenance history.

![]() Capture labor, parts, invoices, and supporting documentation for accurate cost tracking.

Capture labor, parts, invoices, and supporting documentation for accurate cost tracking.

![]() Compare vendor performance, turnaround time, and spend across locations.

Compare vendor performance, turnaround time, and spend across locations.

![]() Prevent billing errors and cost overruns with clear approval workflows and audit trails.

Prevent billing errors and cost overruns with clear approval workflows and audit trails.

Tire Management

Extend tire life, improve safety, and control one of your fleet’s highest maintenance costs.

![]() Track tire inventory, installations, rotations, retreads, and replacements across your fleet.

Track tire inventory, installations, rotations, retreads, and replacements across your fleet.

![]() Monitor tire condition, wear patterns, and service history by asset and position.

Monitor tire condition, wear patterns, and service history by asset and position.

![]() Capture tire-related labor, parts, and vendor costs for accurate cost-per-mile analysis.

Capture tire-related labor, parts, and vendor costs for accurate cost-per-mile analysis.

![]() Identify underperforming tires, vendors, or maintenance practices with real data.

Identify underperforming tires, vendors, or maintenance practices with real data.

![]() Reduce premature replacements and improve uptime with proactive tire maintenance tracking.

Reduce premature replacements and improve uptime with proactive tire maintenance tracking.

Purchasing & Work Request Management

Simplify purchasing and service requests while keeping maintenance costs under control.

![]() Convert approved work orders and requests directly into purchase orders.

Convert approved work orders and requests directly into purchase orders.

![]() Track vendor pricing, part availability, and last price paid to prevent overspending.

Track vendor pricing, part availability, and last price paid to prevent overspending.

![]() Standardize purchasing workflows across shops and locations.

Standardize purchasing workflows across shops and locations.

![]() Capture maintenance issues reported by drivers or staff and route them for approval.

Capture maintenance issues reported by drivers or staff and route them for approval.

![]() Reduce delays, manual entry, and unauthorized purchases with built-in controls.

Reduce delays, manual entry, and unauthorized purchases with built-in controls.

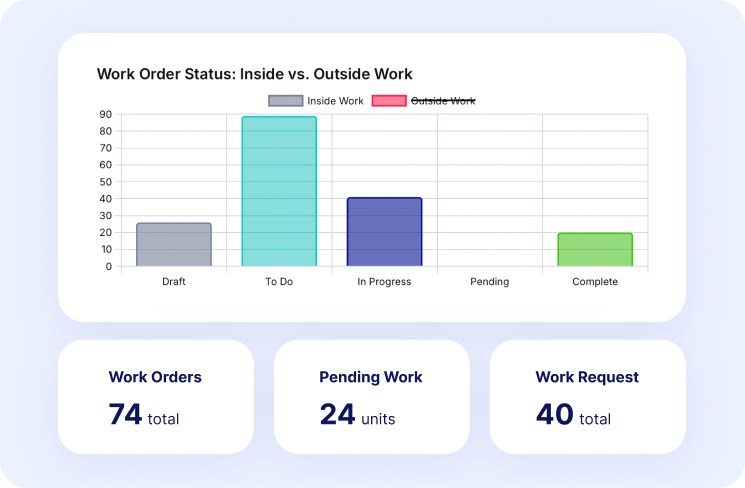

Consolidated Maintenance Visibility

See the full picture of your fleet’s maintenance activity, all in one place.

![]() Centralize preventive maintenance, work orders, inspections, breakdowns, tires, vendors, and purchasing in a single system.

Centralize preventive maintenance, work orders, inspections, breakdowns, tires, vendors, and purchasing in a single system.

![]() View complete maintenance histories by asset, location, or fleet segment.

View complete maintenance histories by asset, location, or fleet segment.

![]() Track downtime, maintenance trends, and recurring issues across your entire operation.

Track downtime, maintenance trends, and recurring issues across your entire operation.

![]() Eliminate disconnected tools, spreadsheets, and manual reporting.

Eliminate disconnected tools, spreadsheets, and manual reporting.

![]() Make faster, more confident decisions with real-time maintenance data you can trust.

Make faster, more confident decisions with real-time maintenance data you can trust.

Consolidated Maintenance Management

Simplify fleet maintenance operations. Centralize data, service records, and maintenance schedules for a complete view of your fleet’s health.

Why Squarerigger?

Optimal Fleet Maintenance

-

Full Maintenance Visibility – Track every repair, inspection, and service record in one fleet maintenance system.

-

Reduce Downtime – Keep vehicles on the road with proactive maintenance planning.

-

Control Costs – Manage vendor expenses, track part usage, and optimize repair workflows.

-

Improve Safety & Compliance – Ensure inspections are completed and fleet safety standards are met.

-

Seamless Integration – Connect maintenance data with inventory, purchasing, and fleet management.