Inventory Management: Optimize Parts & Reduce Costs

What is Fleet Inventory Management?

Managing inventory is a critical challenge for fleet operations and repair shops. Without proper tracking, parts can be overstocked, misplaced, or obsolete leading to wasted capital and disorganized parts space. Squarerigger’s Inventory Management solution ensures that every part is tracked, optimized, and available when needed, reducing costs and improving shop efficiency.

How Squarerigger’s Inventory Tools Streamline Shop Operations

Many fleet managers lack formal inventory training and struggle with high costs, misplaced parts, and manual processes. Squarerigger solves these challenges by providing real-time tracking, barcode scanning, and automated stock level alerts, ensuring a streamlined and cost-effective inventory process.

Benefits of Squarerigger’s Inventory Management Solution

- Eliminate Manual Tracking: Say goodbye to spreadsheets and reduce stock discrepancies.

- Reduce Inventory Costs: Manage excess & obsolete parts, optimize ordering, and avoid stock overages.

- Increase Efficiency: Use barcoding & mobile tools to speed up stock movements.

- Prevent Downtime: Ensure critical parts are always available with real-time tracking & min/max alerts.

- Improve Cost Management: Track purchases against the correct accounts for accurate financial reporting.

- Minimize Supply Chain Disruptions: Stay ahead of vendor backorders, shipping delays, and rising part costs due to market volatility by planning inventory needs and securing parts early.

Key Features of Squarerigger’s Inventory Management

-

Full Inventory Tracking Across Multiple Locations

- Monitor every part moving in and out of your stockroom.

- Track inventory across multiple locations and warehouses.

- Prevent stock discrepancies with real-time inventory updates.

-

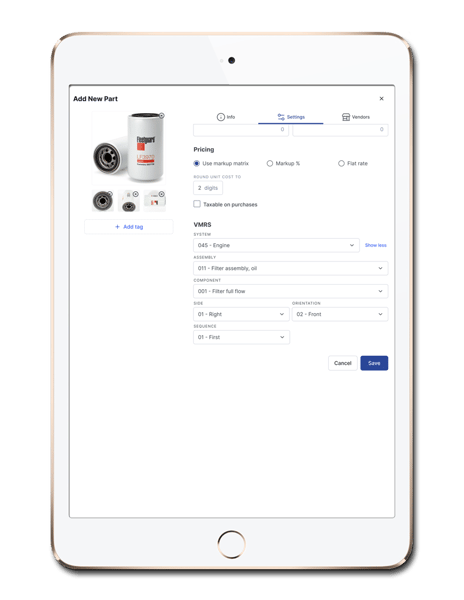

Barcoding for Fast & Accurate Tracking

- Works with any barcode scanner, including mobile phones and tablets, for fast and flexible parts tracking.

- Reduce errors by eliminating manual data entry.

- Support for manufacturer and supplier barcodes, or create your own.

-

Min/Max Stock Levels & Reorder Alerts

- Set minimum and maximum stock levels for essential parts.

- Receive automated alerts when stock is low to trigger reorders.

- Ensure parts availability without excessive stockpiling.

-

Eliminate Excess & Obsolete (E&O) Parts

- Identify slow-moving or obsolete inventory before it ties up capital.

- Easily return unused parts to suppliers or resell them.

- Fleet managers can recover significant inventory value by actively managing E&O parts.

-

Paperless Cycle Counts & Stock Adjustments

- Perform inventory checks without shutting down the stockroom.

- Use mobile devices to conduct stock verifications and adjust levels in real time.

- Reduce inventory errors with automated cycle counts.

-

Streamlined Purchasing & Cost Control

- Automate purchase order creation directly from work orders with QuickBuy.

- Ensure accurate inventory valuation by tracking purchase costs per GL account.

- Prevent overspending with customizable approval workflows.

How Squarerigger Helps Fleet Shops Reduce Inventory Costs

Effective inventory management goes far beyond keeping shelves stocked—it directly impacts your bottom line. Poor visibility, manual processes, and excess or obsolete parts can tie up capital, delay repairs, and distort inventory valuation. Squarerigger turns your inventory from a liability into a strategic asset.

Pain Point: Storeroom Inefficiencies & Tied-Up Capital

Without digital tools and real-time tracking, shops often struggle with:

- Excess & Obsolete Inventory – Parts that haven’t moved in months drain working capital and clog valuable space.

- Inventory Errors – Manual counts and spreadsheet systems increase the risk of stock inaccuracies and missed parts.

- Time-Consuming Reconciliation – Matching physical counts to system data becomes a major disruption.

- Purchasing Disconnects – Overordering or stockouts happen when inventory levels aren’t synced with purchasing workflows.

- Hidden Costs – Poor inventory valuation skews budgeting and reporting, leading to financial surprises.

Solution: Digital Inventory Control with Squarerigger

Squarerigger eliminates storeroom chaos with:

- Real-Time Inventory Visibility – Track every part moving in and out of your stockroom with barcode scanning and automated updates.

- Min/Max Stock Levels – Trigger auto-generated part requests to avoid stockouts and reduce excess inventory.

- Paperless Cycle Counts – Conduct rolling inventory verifications on a mobile device—without halting operations.

- Obsolete Parts Management – Identify slow-moving or inactive items and reclaim capital through returns or resale.

- Flexible GL Cost Allocation – Allocate purchases correctly, even for non-fleet or office supplies, ensuring clean financial reporting.

- AI-Powered Reporting – Generate usage trends, reorder reports, and cost analysis with natural-language queries or export to Excel/CSV.

End Result: Inventory That Works for You

With Squarerigger’s Inventory Management tools, your shop gains: - Reduced Inventory Costs: Eliminate excess, avoid overstocking, and track every part with precision.

- More Accurate Stock Levels: Ensure parts availability without overcommitting capital.

- Improved Uptime: Keep critical parts on hand to support fast, uninterrupted repairs.

- Streamlined Operations: Empower your team with mobile tools and eliminate time-consuming manual processes.

- Financial Accuracy: Maintain clean inventory valuation and cost tracking that supports smarter forecasting.

Take Control of Your Inventory with Squarerigger

Fleet shops and repair operations can’t afford to mismanage parts inventory. Squarerigger’s Inventory Management solution provides real-time tracking, automated stock alerts, and purchasing control, ensuring your shop runs efficiently while reducing costs.

📅 Get a demo today to see how Squarerigger can streamline your inventory management!

Frequently Asked Questions

Have questions? We’ve got answers. See how Squarerigger helps fleets optimize operations, reduce costs, and improve efficiency.

-

Q: How does Squarerigger track inventory across multiple locations?

A: Squarerigger allows centralized tracking of parts stored in multiple warehouses or stockrooms, ensuring real-time visibility across all locations.

-

Q: Can I use barcode scanning with Squarerigger?

A: Yes! Squarerigger supports mobile barcode scanning to log received, issued, and transferred parts with accuracy.

-

Q: How does Squarerigger prevent overstocking and shortages?

A: Min/max stock level settings trigger automatic alerts when inventory falls below the set threshold, ensuring parts are always available without over-purchasing.

Check Out More of Our Shop Management Software Features

Technician Time Management

Squarerigger’s technician time management tools help shops track technician efficiency, identify time waste, and ensure fair labor distribution, giving shop managers clear insights into work time, ancillary tasks, and technician performance trends.

Read MorePurchasing Management

Squarerigger streamlines PO creation, vendor tracking, and real-time reporting, ensuring cost control and procurement efficiency to reduce or eliminate overspending and stock shortages.

Read MoreMulti-Shop Management

Squarerigger offers centralized control, real-time reporting, and multi-location resource sharing, ensuring scalability and operational efficiency for repair shops with multiple locations.

Read More