Preventive Maintenance for Fleets: Maximize Uptime, Reduce Downtime

What is Preventive Maintenance (PM)?

Preventive maintenance involves routine inspections, servicing, and repairs performed on equipment to prevent unexpected breakdowns. For fleets, this means proactively maintaining vehicles and equipment based on time intervals, mileage, or usage metrics—ensuring optimal performance and reliability. Breakdowns can cost up to 10 times more than keeping up with preventive maintenance due to additional parts and labor costs.

How Squarerigger’s Preventive Maintenance Software Can Help Your Fleet

Squarerigger’s preventive maintenance software is designed to help Fleet Managers stay ahead of costly repairs, reduce downtime, and extend the life of their vehicles and equipment. With customizable schedules and real-time tracking, our preventive maintenance software make maintenance easy, efficient, and reliable.

Benefits of Squarerigger’s Preventive Maintenance Solution

- Lower Repair Costs: Prevent minor issues from escalating into costly repairs by addressing them early.

- Extended Asset Lifespan: Proper, consistent maintenance can significantly extend the life of your fleet’s assets.

- Increased Operational Efficiency: With fewer breakdowns, your fleet stays on the road and productive.

- Regulatory Compliance: Maintain compliance with DOT and other safety regulations through documented PM schedules and maintenance records.

- Better Budget Control: Plan for maintenance expenses with predictable servicing schedules and reduced emergency repairs.

Preventive Maintenance Key Features

-

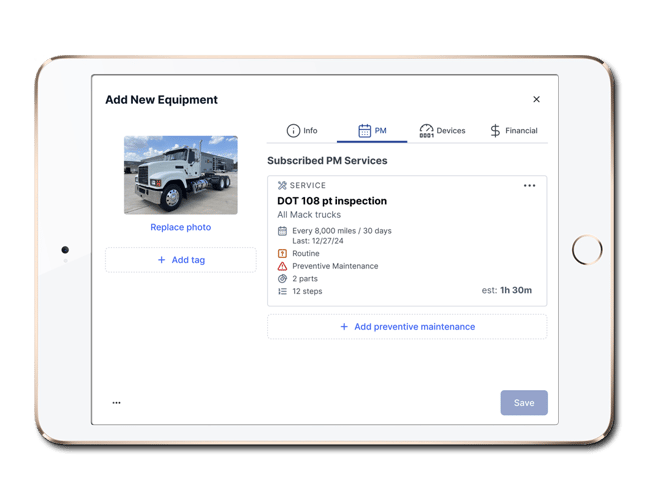

Customizable Maintenance Schedules

- Set PM schedules based on time intervals, mileage, or other equipment-specific metrics.

- Create multiple schedules per asset to track specific maintenance needs (e.g., oil changes, brake inspections, and filter replacements).

-

Automated PM Reminders

- Automate the setup for OEM-recommended preventive maintenance schedules and estimated labor requirements.

- Receive automated notifications and reminders to ensure no maintenance task is overlooked.

- Keep your team on schedule with alerts that prevent last-minute emergencies and unexpected repairs.

-

Accurate Tracking with Telematics Integration

- Squarerigger integrates seamlessly with telematics systems to pull real-time odometer readings, engine hours, and diagnostic codes.

- Ensure accurate data feeds into your PM schedules, reducing manual updates and potential errors.

-

Maintenance History Tracking

- Easily access detailed maintenance histories for each vehicle or asset.

- Quickly review past services, inspections, and repairs to ensure compliance and reduce duplicate work.

-

Minimize Downtime, Maximize Uptime

- Ensure that maintenance tasks are completed before they result in costly breakdowns.

- Efficient scheduling keeps your vehicles on the road longer and reduces the chance of unplanned downtime.

-

Maintenance Planning & Resource Optimization

- Use PM insights to plan resource allocation, technician schedules, and parts availability.

- Streamline maintenance workflows to reduce repair costs and improve shop productivity.

How Preventive Maintenance Helps Your Bottom Line

Fleets that implement a comprehensive preventive maintenance strategy experience fewer unexpected expenses, reduced downtime, and improved fleet reliability. Squarerigger’s fleet maintenance software makes managing PMs easy, providing full visibility into maintenance activities and ensuring your fleet operates efficiently.

Implementing a robust Preventive Maintenance (PM) program is essential for fleet managers aiming to minimize unexpected breakdowns and optimize operational efficiency. Unplanned vehicle failures can lead to significant expenses, including towing services, lost productivity, potential lodging for drivers, and customer dissatisfaction. In fact, the average vehicle downtime averages around $625 per day.

Pain Point: The High Cost of Reactive Maintenance

Relying solely on reactive maintenance - addressing issues only after they occur - can lead to:

- Elevated Repair Expenses: Emergency repairs often incur higher costs due to expedited services and potential overtime labor charges.

- Operational Disruptions: Unexpected breakdowns can halt operations, leading to missed deadlines and reduced customer satisfaction.

- Safety Risks: Sudden equipment failures can pose significant safety hazards to both operators and other road users.

Solution: Proactive Preventive Maintenance with Squarerigger

Squarerigger’s PM solution offers a proactive approach by:

- Scheduling Regular Inspections: Routine checks ensure that potential issues are identified and addressed before they escalate.

- Automating Maintenance Tasks: Timely servicing of components based on usage metrics prevents unexpected failures.

- Utilizing Data-Driven Insights: Leveraging telematics and historical data to predict and prevent potential breakdowns.

End Result: Enhanced Efficiency and Cost Savings

By implementing Squarerigger's preventive maintenance tools, fleets can achieve: - Reduced Downtime: Ensuring vehicles remain operational and productive.

- Lower Maintenance Costs: Addressing minor issues before they become major repairs leads to significant cost savings.

- Extended Asset Lifespan: Regular maintenance contributes to longer vehicle and equipment life, maximizing return on investment.

Incorporating a preventive maintenance strategy not only safeguards your fleet's reliability but also positively impacts your bottom line by reducing unexpected expenses and enhancing operational efficiency.

Frequently Asked Questions

Have questions? We’ve got answers. See how Squarerigger helps fleets optimize operations, reduce costs, and improve efficiency.

-

Q: How often should preventive maintenance be performed on fleet vehicles?

A: The frequency of PM depends on factors like the type of asset, manufacturer recommendations, and operating conditions. Squarerigger’s customizable schedules ensure you maintain assets according to their specific requirements.

-

Q: Can Squarerigger’s preventive maintenance solution help with compliance?

A: Yes! Squarerigger tracks maintenance histories, inspections, and repairs, making it easier to demonstrate compliance with industry regulations and audits.

-

Q: What types of maintenance can be scheduled through Squarerigger’s PM module?

A: You can schedule a variety of tasks, such as oil changes, brake inspections, tire rotations, fluid checks, filter replacements, and more.

Check Out More of Our Fleet Maintenance Software Features

Work Order Management

Squarerigger’s work order management system provides the tools you need to standardize processes, eliminate inefficiencies, and ensure every repair is tracked, completed, and billed accurately.

Read MoreInspections

Squarerigger's inspection management tools help fleet managers ensure that every vehicle meets safety and compliance requirements, without the hassle of paperwork.

Read MoreOutside Work

Squarerigger provides a centralized platform to manage external service providers, helping you maintain accurate records, control costs, and ensure timely repairs.

Read More