Service Coding (VMRS): Standardize Maintenance Tracking & Unlock Cost Insights

What is VMRS & Why Does It Matter?

Vehicle Maintenance Reporting Standards (VMRS) is a universal coding system developed by the ATA Technology & Maintenance Council (TMC) to standardize the way fleets track repairs, maintenance, and parts usage. Introduced in 1970 and continually updated to meet modern needs, VMRS helps fleets organize service records, analyze costs, and benchmark performance with industry-standard precision.

By coding maintenance activities consistently, fleet managers gain clean, actionable data for improving preventive maintenance (PM) schedules, optimizing inventory, tracking warranty recoveries, and reducing downtime.

How Squarerigger’s VMRS Tools Improve Fleet Operations

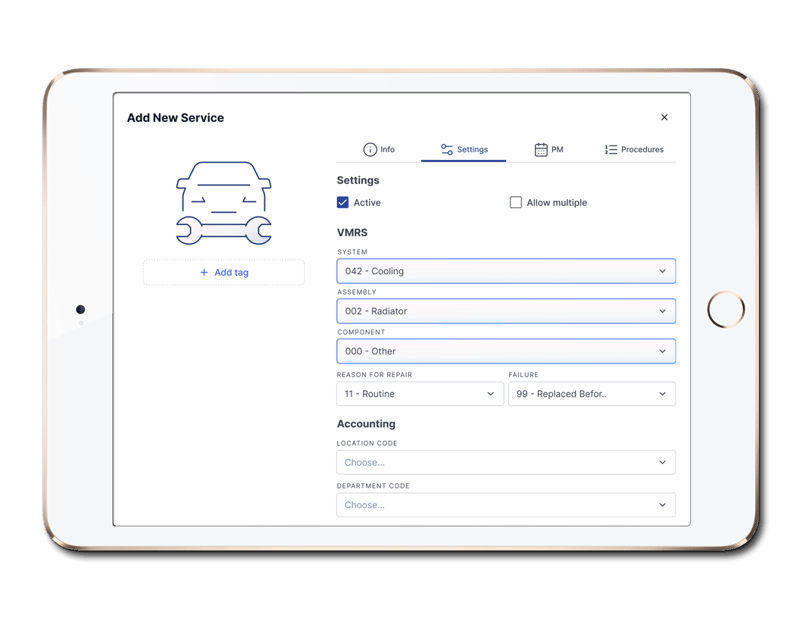

Squarerigger’s built-in VMRS service coding automatically categorizes every repair, service event, and part replacement. By eliminating manual entry errors and ensuring uniform tracking, Squarerigger enables fleets to transform messy service data into powerful insights for smarter decision-making, cost control, and operational improvement.

Benefits of Squarerigger’s VMRS Service Coding Solution

- Standardized Maintenance Tracking: Eliminate guesswork with consistent service and parts categorization.

- Accurate Cost Analysis: Track repair, labor, and parts costs by system, assembly, and component.

- Improved Preventive Maintenance (PM) Strategies: Refine PM schedules based on failure trends.

- Optimized Warranty Recovery: Use standardized coding to submit faster, more successful warranty claims.

- Better Budget Control: Plan for maintenance expenses with predictable servicing schedules and reduced emergency repairs.

- Smarter Inventory Management: Stock parts based on real-world usage and failure rates.

- Streamlined Technician Workflow: Speed up work order entry and reduce coding errors.

- Smarter VMRS Capture: Technicians don’t need to memorize codes—Squarerigger simplifies VMRS by translating plain-language service tasks into the correct codes automatically.

Key VMRS Features in Squarerigger

-

Standardized Work Order & Service Tracking

- Automatically assign VMRS codes during repair and maintenance activities.

- Ensure clean, consistent repair records across all assets and service centers.

- Improve historical trend analysis for preventive and predictive maintenance planning.

-

Accurate Repair & Labor Cost Analysis

- Capture labor and parts costs by VMRS code for precise tracking.

- Benchmark maintenance expenses against industry standards.

- Highlight high-cost repairs and recurring failure areas for budget forecasting.

-

Maintenance Benchmarking & Compliance Reporting

- Compare service performance across your fleet—or against industry averages.

- Generate detailed, audit-ready reports using VMRS-coded histories.

- Support compliance efforts with structured documentation.

-

Warranty Tracking & Cost Recovery

- Use VMRS failure codes to strengthen warranty claims and reimbursement rates.

- Isolate warranty-related costs from general maintenance spend.

- Maximize manufacturer credits by aligning repairs with correct failure descriptions.

-

Parts & Inventory Management Optimization

- Link parts usage to VMRS failure trends.

- Adjust stock levels based on actual repair needs—reducing dead stock.

- Identify frequently failing components to inform purchasing and vendor negotiations.

-

Technician Productivity Improvements

- Predefined VMRS codes speed up work order creation.

- Eliminate inconsistent data entry and improve reporting quality.

- Help technicians find the right service code faster for quicker job completion.

How VMRS Standardization Impacts Fleet Operations

Inconsistent maintenance records make it nearly impossible to accurately track costs, identify problem areas, or optimize fleet operations. Without standardization, Fleet Managers rely on anecdotal evidence instead of hard data, leading to preventable breakdowns, lost warranty claims, and inefficient repair practices. VMRS transforms maintenance tracking from a burden into a business advantage.

Pain Point: Disorganized Maintenance Records & Rising Costs

Without VMRS coding, fleets often struggle with:

- Inconsistent Work Orders: Manual service descriptions make historical data messy and unreliable.

- Poor Cost Visibility: Labor and parts costs are difficult to analyze or forecast accurately.

- Missed Warranty Claims: Lack of structured failure tracking leads to lost reimbursement opportunities.

- Inefficient Inventory Management: Stocking parts without data-driven insights wastes capital and shelf space.

- Technician Frustration: Manual coding wastes time and leads to errors that impact billing and reporting.

Solution: Smart Service Tracking with Squarerigger’s VMRS Tools

Squarerigger eliminates these challenges by:

- Standardizing Service Data: Assigning VMRS codes automatically to repairs, parts, and failures.

- Enabling Deeper Cost Analysis: Breaking down spend by component, system, or failure type.

- Boosting Warranty Recovery: Linking warranty claims to proper failure descriptions for faster approvals.

- Optimizing Parts Management: Analyzing parts usage patterns to improve inventory decisions.

- Streamlining Technician Workflow: Speeding up work order creation with pre-coded options.

End Result: Cleaner Data, Smarter Decisions, Lower Costs

By implementing Squarerigger’s VMRS-powered service tracking, fleets achieve: - More Accurate Maintenance Records

- Lower Repair & Inventory Costs

- Higher Warranty Reimbursement Success

- Faster, More Accurate Work Orders

- Improved Preventive Maintenance Schedules

With structured service data at your fingertips, your fleet becomes more efficient, cost-effective, and audit-ready.

Frequently Asked Questions

Have questions? We’ve got answers. See how Squarerigger helps fleets optimize operations, reduce costs, and improve efficiency.

-

Q: What does VMRS stand for?

A: Vehicle Maintenance Reporting Standards—a universal coding system for tracking fleet maintenance activities.

-

Q: How does VMRS improve maintenance reporting?

A: It standardizes service descriptions, allowing consistent tracking of repairs, costs, failures, and preventive maintenance effectiveness.

-

Q: Who developed VMRS codes and why?

A: VMRS was developed by the ATA’s Technology & Maintenance Council (TMC) to create a standardized language for documenting vehicle repairs, parts, and service tasks across the fleet industry.

-

Q: How are VMRS codes structured?

A: VMRS codes use a hierarchical 9-digit format split into three groups: System (first 3 digits), Assembly (middle 3 digits), and Component (last 3 digits), allowing for precise classification of maintenance events.

-

Q: Do technicians need to memorize VMRS codes?

A: No. In Squarerigger, technicians select tasks in plain language. The system automatically maps them to the correct VMRS codes to reduce errors and save time.

-

Q: Can VMRS codes help with warranty tracking?

A: Yes. VMRS codes improve warranty recovery by clearly documenting component failures and aligning service descriptions with manufacturer requirements.

-

Q: How does VMRS impact parts inventory management?

A: By linking parts usage to VMRS failure codes, fleets can identify frequently failing components, reduce overstock, and make smarter purchasing decisions.

-

Q: Are VMRS codes required for DOT or FMCSA compliance?

A: VMRS is not mandatory, but it supports compliance by creating structured, audit-ready service records that demonstrate maintenance diligence and safety practices.

-

Q: How often are VMRS codes updated?

A: VMRS codes are continuously maintained and updated by the TMC to reflect new technologies, components, and maintenance practices in the transportation industry.